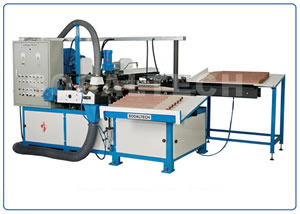

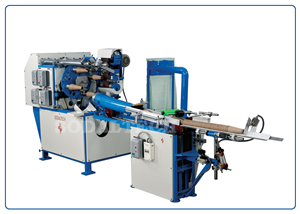

Salient Features

- High performance machine with output up to 55 cones per minute @ 100% efficiency

- For standard cone tapers such as 9 DEG 15′,5 DEG 57′, 4 DEG 20′ & 3 DEG 30′ etc

- Unique Patented Gripper Winding system which ensures minimum process wastage with less power impact.

- Finger Touch Paper Reel Loader

- Easy Reel Shifter

- Reel Tensioning Devices

- Rapid setting and size changeover facility

- Latest type glue applicator

- Waste paper exhaust system

- Online Printer for precise single or multicolour Printing with great flexibility of standard designs as shown in the colour chart.

- Drier can be heated with multiple source of energy such as coal or firewood or gas or steam or electric or thermic heating with automatic energy saving device.

- Inner logo printer (Optional)

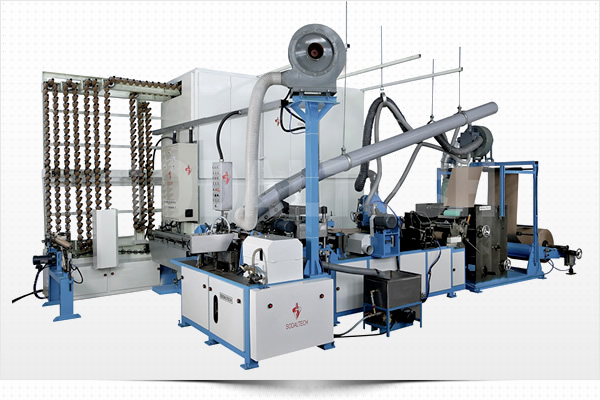

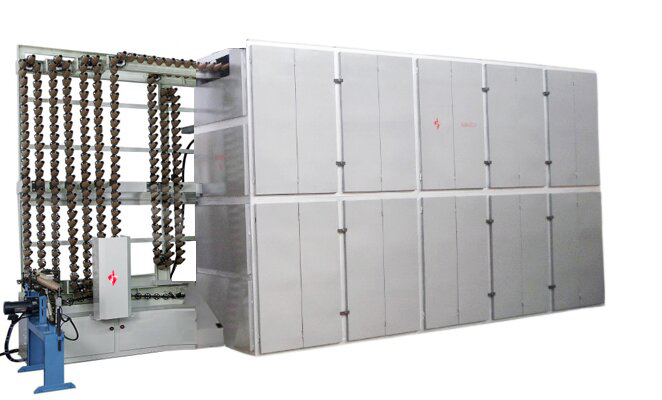

Textile Paper Cone Drier

SODALTECH Automatic On-Line Conveyorised Paper Cone Drier Model CD50K (E) with capacity matched to the output of Automatic Cone winding machine. Fitted with suitable electric heaters and blower with motor

Technical Features :

a. Well insulated doors and metal enclosures for energy saving

b. Automatic Temperature control

c. Safety device for overload prevention

d. Provision to operate at variable speeds

e. Auto Control equipment for Chain Conveyor tension

f. Suitable Drive motor with control panel

g. Delivery conveyor for dried cones with automatic nesting of cones

h. Ejection device to transfer nested cones to finishing process

Connected load :

45 KW for heaters

4.07 KW (for motor drives and fan blower

Machine Dimensions : 6.5 metres length x 1.7 metres width x 3.7 metres height.

Drier working temperature will be 70 Deg C to 90 Deg C depending on the site working conditions